At the Arctic Subsea Resource Development Summit, experts, engineers, and stakeholders from around the world gathered to address one of the most ambitious engineering frontiers on the planet: subsea operations in the polar regions. Among the standout presentations was one by Esimtech, showcasing their cutting-edge subsea oil production system designed specifically for the unforgiving conditions of the Arctic.

At the Arctic Subsea Resource Development Summit, experts, engineers, and stakeholders from around the world gathered to address one of the most ambitious engineering frontiers on the planet: subsea operations in the polar regions. Among the standout presentations was one by Esimtech, showcasing their cutting-edge subsea oil production system designed specifically for the unforgiving conditions of the Arctic.

Meeting the Challenges of the Arctic

The Arctic presents a unique set of obstacles for offshore oil and gas development. Temperatures can plunge to -40°C, sea ice forms rapidly and unpredictably, and maintenance windows are narrow due to extreme weather and limited daylight. In such an environment, conventional subsea systems are simply not enough.

Esimtech's solution? A specially engineered subsea system designed from the ground up to endure polar extremes, maintain thermal stability, and continue reliable operations in remote under-ice environments.

Showcasing Innovation: Physical Models & Multimedia Demonstrations

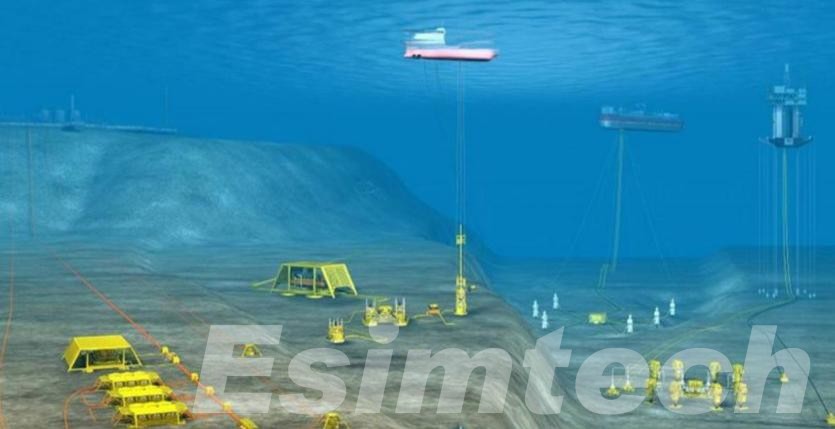

During the summit, Esimtech combined detailed physical models with high-definition video to provide an immersive overview of their Arctic subsea solutions. This hybrid demonstration format helped attendees better understand how each component functions in harsh subsea conditions.

The centerpiece of their presentation was a scaled model of their polar subsea infrastructure, including risers, manifolds, flowlines, and control modules—all engineered for deployment beneath thick, mobile ice sheets.

Engineering Highlights: Built for Extremes

One of the core features of Esimtech's Arctic-ready systems is their use of low-temperature resistant materials. Every component in the system—from seals and casings to control units—is fabricated using alloys and polymers rated for cryogenic performance, ensuring durability even when exposed to prolonged sub-zero conditions.

Another critical innovation is the system’s ice-resistant structural design. Unlike conventional subsea systems that may suffer under pressure from floating ice masses or ice keels, Esimtech’s architecture distributes loads and minimizes vulnerability through reinforced housing and strategic placement.

To maintain fluidity of hydrocarbons in deepwater pipelines, Esimtech employs a proprietary thermal insulation layer—a combination of aerogel-based insulation and vacuum jacket technology—that prevents hydrate formation and wax buildup, which are major risks in ultra-cold environments.

Smart Monitoring: Real-Time Data from the Deep

These advanced systems are also embedded with a sophisticated network of sensors capable of continuously measuring temperature, pressure, and flow rate. Using edge computing, the system can identify anomalies such as leaks, pressure drops, or potential freezing events, sending real-time alerts to surface operators.

This level of smart automation is a key aspect of Esimtech’s broader commitment to safe, efficient, and intelligent subsea resource extraction.

Operational Experience in Polar Waters

Esimtech has already begun applying these innovations in real-world Arctic deployments. In their presentation, the company shared results from pilot projects in northern offshore fields, including successful long-duration tests and operations in ice-covered waters.

One case study focused on a subsea production module deployed off the northern Norwegian coast. Despite temperatures ranging from -25°C to -35°C and frequent ice floes, the system maintained continuous uptime over a 12-month period with no recorded mechanical failures.

Commitment to the Future of Arctic Development

With global interest in Arctic resource development rising, the demand for resilient and sustainable subsea solutions is more urgent than ever. Esimtech’s presentation not only highlighted the technical excellence of their systems but also reinforced the company’s reputation as a leader in adapting subsea production systems to meet tomorrow’s challenges.

Their approach—rooted in innovation, rigorous field testing, and a deep understanding of polar engineering—is earning them growing recognition among governments, operators, and private-sector stakeholders seeking to unlock the Arctic's energy potential responsibly.